Plasma Cutter for CNC Table

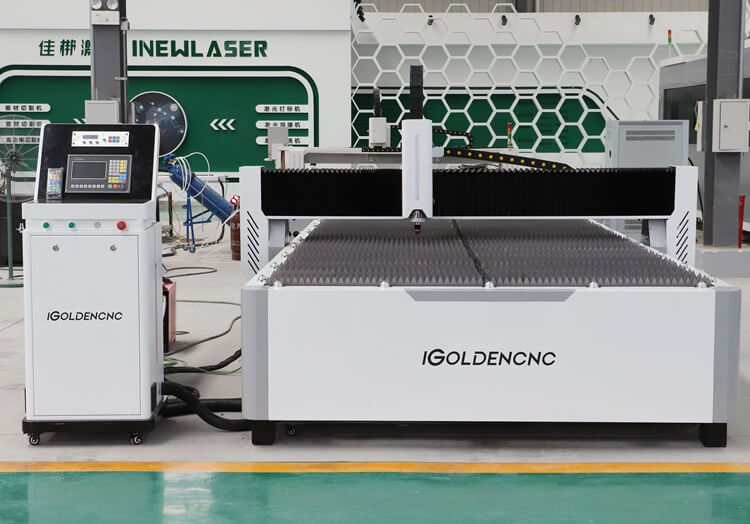

Desktop plasma cutting machine is a high-efficiency, high-precision, and high-reliability thermal cutting equipment that combines computer control, precision mechanical transmission, and plasma cutting technologies. CNC plasma table machine, including flat plasma cutting machine, plate and tube integrated plasma cutting machine, square tube plasma cutting machine.

The reinforced bed makes the equipment more stable during operation, compared with portable plasma cutting machine and gantry plasma cutting machine, desktop plasma cutting machine has the advantages of fast speed and high precision, and is more suitable for batch processing of medium and thin plates.

Best Plasma Cutter for CNC Table

CNC plasma tables by iGOLDEN provide a broad range of cutting solutions. Designed for top-notch cut quality, a iGOLDENCNC plasma table is durable enough to run full production for years, yet nimble enough to cut intricate shapes with ease. iGOLDEN is here to help you select the best CNC plasma cutting table to meet your specific needs.

The most common types of CNC plasma tables include 4×4 plasma table, 4×8 plasma table, 5×10 plasma table and 6×12 foot plasma table. Some users may call CNC plasma table 48 “X 48” and 48 “x 96”, 60 “x 120” in inches, and some users of the CNC plasma tables may call worktable kits 1212, 1325, 1530, 2040, in millimeters (mm).

Industrial CNC cutting table system offers all the features to get started on cutting carbon steel, stainless steel and non-ferrous metal in any 2D graphics. The included Digital Torch Height Controller maintains distance between the plasma torch and your work – producing smooth edges, sharp details and high precision.

What is the working principle of the CNC plasma table machine?

The method of using the thermal energy of the plasma arc to melt the material to be cut is called plasma arc cutting, which uses high-speed, high-temperature and high-energy plasma to quickly heat and melt the material to be cut, and with the help of internal or external high-speed gas (water) flow.

The material is discharged until the plasma jet penetrates the back of the workpiece to form an incision, so as to achieve the purpose of cutting.

The temperature of the plasma arc column is extremely high, reaching 10,000°C to 30,000°C, far exceeding the melting point of all metallic or non-metallic materials. Therefore, the plasma arc cutting process does not rely on oxidation reaction, but on melting to cut materials. Its cutting application range is much larger than that of oxygen cutting, and it can cut almost all metals, non-metals, multilayers, and composite materials. And its cut is narrow (medium and thin plates), the quality of the cutting surface is good, the cutting speed is fast, and the cutting thickness can reach 160mm. Due to the high temperature and high speed of the plasma arc, it will not deform when cutting thin plates (≤0.5mm). Especially in the field of cutting stainless steel, titanium alloy, and non-ferrous metal materials, the choice of plasma cutting can not only achieve satisfaction The cutting quality can also obtain economic benefits that are ten times more than the original process. Therefore, plasma cutting has been more and more widely used in all walks of life.

CNC plasma cutting Applications

The plasma cutting machine can cut various metals that are difficult to cut by oxygen cutting with different working gases, especially for non-ferrous metals (aluminum, copper, titanium, nickel), the cutting effect is better; such as stainless steel, carbon steel, mild steel iron plate, aluminum plate, plated,copper etc. And could add flame head for cutting more thicker metal within 300mm. Thus it is widely applied in industries such as machinery, automobile, shipbuilding, petro-chemical, war industry, metallurgy, aerospace, boiler and pressure vessel, locomotive etc.

The main advantage of zinc plate, white steel plate and titanium plate is that when cutting metal with small thickness, the plasma cutting speed is fast, especially when cutting ordinary carbon steel sheet, the speed can reach 5~6 times of oxygen cutting method. The surface is smooth, the thermal deformation is small, and there is almost no heat affected zone.

What are the advantages of plasma cutting?

Plasma cutting is an effective cutting method of metal plate and metal pipes. The CNC plasma cut machine has been widely used in many different industries. Customers of the CNC plasma cut machine can benefit from 10 advantages, including fast cutting, ease of use, low cost, multitasking, versatility, safe use, eliminating plate warpage, a wide range of materials and thickness, improving internal perforation speed and reducing slag.

Compared with the traditional semi-automatic and manual cutting methods for the metal, the full-automatic CNC plasma cut machine greatly improves the efficiency and quality. Plasma cnc machine cutting system is an exponentially controlled plasma, flame, water jet and laser cutting machine. According to the CNC nesting software for automatic, full-time, high-quality, high utilization and efficient cutting. In industrial production, metal thermal cutting generally includes gas cutting, plasma cutting and laser cutting.

Compared with gas cutting, plasma cutting has wider cutting range and higher efficiency. Fine plasma cutting technology is close to the quality of laser cutting in the cutting surface quality of materials, but the cost is much lower than that of laser cutting. It shows great advantages in saving materials and improving labor productivity. This promotes the development of plasma cutting technology from manual or semi-automatic to CNC, and has become one of the main development directions of CNC cutting technology.

1.The plasma CNC machine can cut thick metals, for example, stainless steel, aluminum and its alloys, copper and its alloys, cast iron and other metal materials. Customers can also use a non transfer plasma arc cutting gun to cut non-conductive non-metallic materials and insulating materials with a thickness of more than 150mm.

2.The cutting speed of plasma CNC machine is fast and the production efficiency is high, especially when cutting thin metal with high power, the production efficiency of plasma CNC machine is improved more significantly.

3.The cutting quality of plasma CNC machine is high, the incision is smooth and flat, the incision is narrow, and the heat affected zone and deformation are smaller than other cutting methods.

4.The cost is low of plasma CNC machine. Due to the high speed, cutting the same material with cheap gas such as nitrogen requires less raw materials and labor than other methods.

How many types of plasma cutting machines?

The most common types of CNC plasma cutting machines include handheld plasma cutting machines (portable plasma cutting machines) and CNC plasma cutting machines (hobby CNC plasma and Industrial CNC plasma). The most common plasma power sources for the CNC plasma cut machine include Huayuan brand plasma cutter and American Hypertherm plasma cutter. According to the appearance type, CNC plasma cut machine can be divided into desktop CNC plasma, gantry CNC plasma and portable CNC plasma.

According to the working mode of CNC plasma cut machine, it can be divided into dry plasma, semi dry plasma and underwater plasma. According to the cutting quality,the CNC plasma cut machine can be divided into ordinary plasma, fine plasma, laser plasma, etc.

Discussion (0)

There are no comments for this doc yet.