Laser welding and cutting machine with all in 1 function. Laser welding, laser cutting, laser cleaning and weld cleaning in 1 compact device. Laser welding has many advantages over conventional welding techniques – the experts know it and have been using it for a long time. This type of machine typically combines different capabilities related to laser processing. Combining these functions into a single handheld device offers several advantages, including increased efficiency, reduced setup time, and enhanced versatility in various applications.

Laser Welding and Cutting Machine

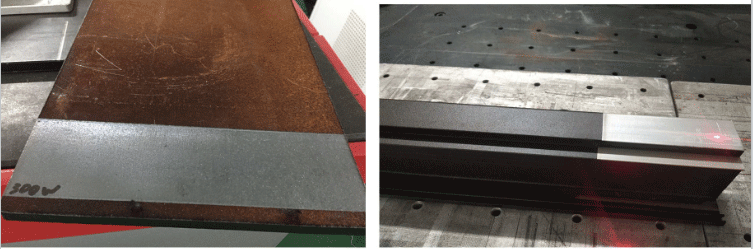

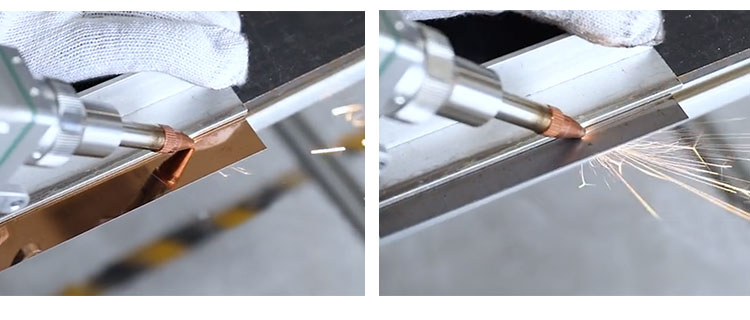

Laser cutting and welding machine is composed of fiber laser generator, handheld laser gun, water chiller, and all in 1 control system, which is used for laser welding, cleaning and handheld cutting. Each handheld laser gun is portable, convenient, and easy to use.When you need to handle different processes, you can quickly change nozzles, lenses, and control systems.The fiber laser cutting and welding machine can clean oxides and rust on metal surfaces, and can also perform welding and cutting functions. It is a three-in-one welding, cutting and cleaning equipment. The device has three modes that can be switched freely. all-in-1 Handheld Laser Welding and Cutting Machine can not only cut and weld metal but also clean rust, paint, resin, coating, oil, and stains.

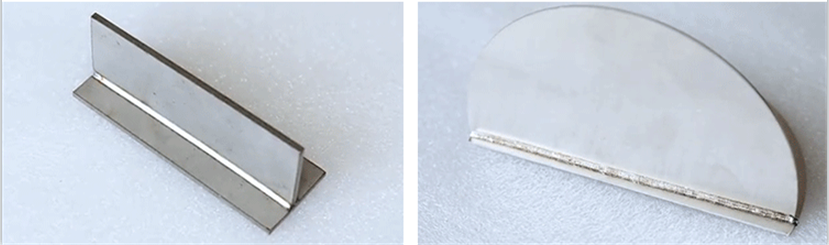

A laser cutting and welding machine uses a high-powered laser beam to cut and weld materials with exceptional precision. The machine can switch between cutting and welding modes, making it ideal for applications that require both processes. It is commonly used for metals like steel, aluminum, and titanium, as well as plastics and composites.

Advantages of Laser Welding and Cutting Machine

- Lightweight flexible, simple and convenient operation, can satisfy the welding/cleaning/cutting triad, need not change point;

- Portable welding head adopts protection lens and focus lens, collimating lens are all made of withdrawable type installation, convenient customer self repair change, constantly monitor the temperature;

- High Precision: Achieves accurate cuts and welds with minimal heat-affected zones.

- Versatility: Can handle a wide range of materials and thicknesses.

- Automation: Reduces manual labor and increases efficiency through CNC control.

- Dual Functionality: Combines cutting and welding in a single machine, saving space and cost.

- Clean Operations: Produces clean edges and welds with minimal burrs or deformations.

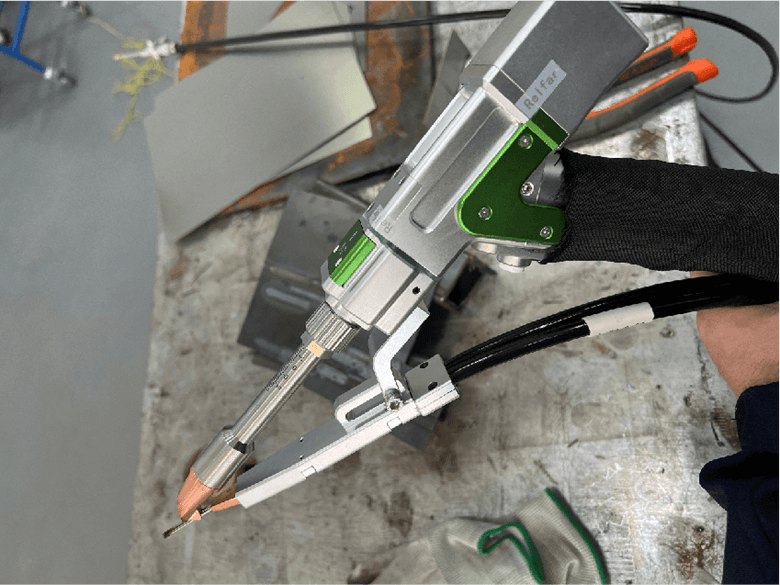

Four-in-One Laser Head

The handheld laser head has a simple appearance, is small and light, and can be used by hand for a long time. The integrated design of the button and handle is simple and easy to use. It can realize three functions of welding, cleaning, and cutting through the intelligent controller according to different usage scenarios, truly realizing three functions in one machine.

Fiber Laser Welding Gun

The handheld type laser gun can do welding, cleaning, and cutting with smart controller, easy to use for flexible machining, portable with small size, low cost without consumables.

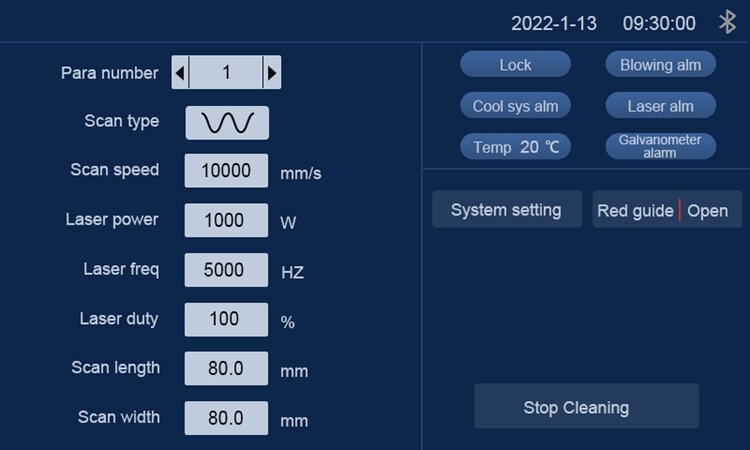

Intelligent Control System

Polymerization control function, humanized design, easy to operate.

Multiple swing modes: Line, Circle, Snowflake, Bullhead, Hot Wheels.

Support the process parameter library, which can realize the rapid storage and recall of cleaning process parameters.

Multi-language support CN, EN, RU, KR, VN, JP.

Real-time monitoring and automatic alarm, safe production and quick troubleshooting.

Fiber Laser

Stable performance, low energy consumption, low failure rate, flexible optical fiber 5-20m, flexible and convenient, can achieve outdoor work, and has a rigid protective layer.

Laser Welding and Cutting Machine Applications

Laser Cleaning, Welding, Cutting Machine

- Automotive Industry:Cutting and welding car body parts, chassis components, and exhaust systems.

- Aerospace Industry:Precision cutting and welding of aircraft components and engine parts.

- Metal Fabrication:Cutting and welding sheet metal, pipes, and structural components.

- Electronics Industry:Cutting and welding small, intricate components for electronic devices.

- Medical Industry:Fabricating and welding medical devices and surgical instruments.

- Jewelry Making:Cutting and welding precious metals for intricate designs.

Discussion (0)

There are no comments for this doc yet.