| You are currently viewing a revision titled "5 Axis CNC Wood Router", saved on June 2, 2025 at 7:47 pm by Milne Fyhn | |

|---|---|

| Title | 5 Axis CNC Wood Router |

| Content | A 5-axis CNC wood router is used for cutting, carving, and shaping wood material. It utilizes five axes of motion to achieve complex and precise cuts in three-dimensional space. The three linear axes (X, Y, and Z) control the movement of the cutting tool along the length, width, and depth of the workpiece, respectively. The two additional rotational axes (A and B) enable the tool to tilt and rotate, allowing for intricate cuts from various angles.

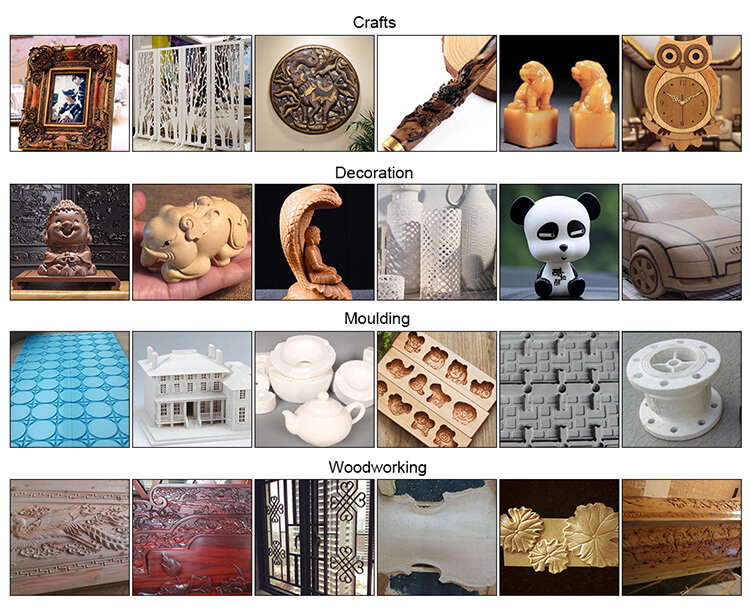

The five-axis capability allows for intricate 3D carving, enabling the creation of detailed and realistic designs on wood.

5 axis router machine applications including1. Edge trimming of thermoformed plastic, molded plastic and composite parts. The flexibility of the CNC machine creates the ability to provide high quality finishing and edge trimming on many manufactured plastic items. 2. Deep cavity mold making. On three-axis machines deep cavity mold making requires that you have longer tools to be able to reach deep enough. Having longer tools results in the user having to reduce cutting speed to prevent breakage. With the added movement provide by 5 axis machining, shorter tools can be used, and your cutting speed can be increased. 3. Molded plywood chairs and decorative furniture parts. The machine allows for unique shaping and molding of various materials, allowing you to make your creative and dynamic designs a reality. 4. Detailed 3D carvings. The increase in movement of the cutting tool on the machine allows it to carve intricate designs into a piece of material. It allows you to capture the fine details of your design in the job you are cutting.

How choosing a 5-axis CNC router for woodworking?When looking for a 5-axis wood CNC router, consider factors such as machine size, spindle power, software compatibility, and budget. Additionally, it’s essential to review the specifications of various models and consult with manufacturers or distributors to find the machine that best suits your specific woodworking needs. Machine Size

Consider the size of the machine’s work envelope to ensure it can accommodate the size of the woodworking projects you typically work on. Precision and Accuracy: Look for a machine with high precision and accuracy to achieve the level of detail and quality you need in your woodworking projects.

Speed and Efficiency

Evaluate the machine’s speed and efficiency to determine how quickly it can complete tasks without sacrificing quality. Software Compatibility: Ensure that the machine is compatible with the CAD/CAM software you plan to use for design and toolpath generation.

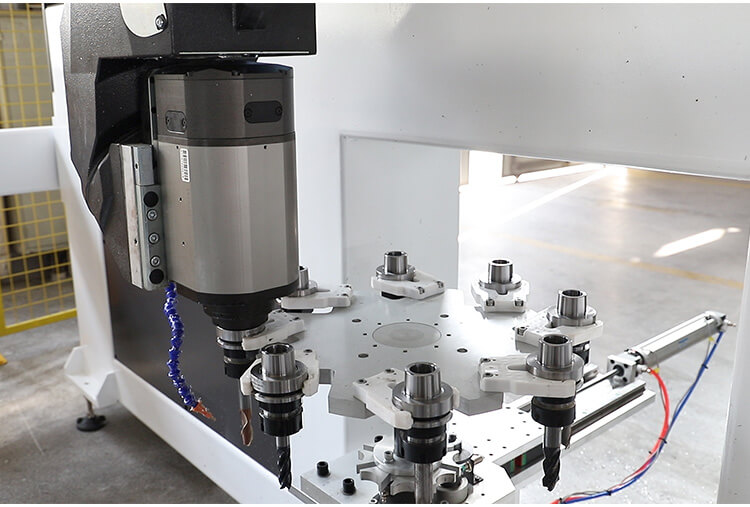

Tool Changer

An automatic tool changer (ATC) can improve productivity by allowing the machine to change cutting tools automatically during the machining process.

Spindle Power

The spindle’s power and speed should match the type of woodworking you do. Different projects may require different spindle capabilities.

Dust Collection System

A built-in dust collection system can help maintain a clean work environment and prolong the life of the machine.

Price and Budget

Determine your budget and find a machine that offers the best features within that budget. Keep in mind that 5-axis CNC routers can vary widely in price.

Brand and Support

Consider purchasing from reputable manufacturers or suppliers that offer good customer support and service.

Reviews and Recommendations: Seek out reviews and recommendations from other woodworking professionals or hobbyists who have experience with 5-axis CNC routers. Warranty and Maintenance: Inquire about the warranty and maintenance requirements to ensure long-term reliability and support.

Machine Size

Consider the size of the machine’s work envelope to ensure it can accommodate the size of the woodworking projects you typically work on. Precision and Accuracy: Look for a machine with high precision and accuracy to achieve the level of detail and quality you need in your woodworking projects.

Speed and Efficiency

Evaluate the machine’s speed and efficiency to determine how quickly it can complete tasks without sacrificing quality. Software Compatibility: Ensure that the machine is compatible with the CAD/CAM software you plan to use for design and toolpath generation.

Tool Changer

An automatic tool changer (ATC) can improve productivity by allowing the machine to change cutting tools automatically during the machining process.

Spindle Power

The spindle’s power and speed should match the type of woodworking you do. Different projects may require different spindle capabilities.

Dust Collection System

A built-in dust collection system can help maintain a clean work environment and prolong the life of the machine.

Price and Budget

Determine your budget and find a machine that offers the best features within that budget. Keep in mind that 5-axis CNC routers can vary widely in price.

Brand and Support

Consider purchasing from reputable manufacturers or suppliers that offer good customer support and service.

Reviews and Recommendations: Seek out reviews and recommendations from other woodworking professionals or hobbyists who have experience with 5-axis CNC routers. Warranty and Maintenance: Inquire about the warranty and maintenance requirements to ensure long-term reliability and support.

5 Axis wood Router Machine Buyer’s GuideMachine Size and Capacity: Determine the required size and capacity of the CNC router based on your specific needs. Consider the maximum workpiece dimensions and weight that the machine can accommodate. Ensure that the machine’s size and capacity align with your intended applications and production requirements. Axis Configuration: A 5-axis CNC router offers the ability to perform complex machining operations by moving the cutting tool along five axes: X, Y, Z, and two rotational axes (A and C). Evaluate the machine’s axis configuration and verify that it meets your project requirements for multi-sided machining, intricate designs, and complex geometries. Spindle Power and Speed: The spindle is a critical component of a CNC router, responsible for cutting, routing, and shaping operations. Consider the power and speed of the spindle to ensure it can handle your desired materials and cutting requirements. Higher power and variable speed capabilities offer greater versatility and efficiency. Control System and Software: The control system and software play a vital role in operating and programming the CNC router. Ensure that the machine is equipped with a reliable and user-friendly control system, along with compatible software that supports your design and machining needs. Look for features such as CAD/CAM compatibility and ease of programming. Precision and Accuracy: Precision and accuracy are crucial in CNC machining. Look for a machine that offers high positioning accuracy and repeatability. Consider factors such as the rigidity of the machine structure, quality of linear guides and bearings, and the capability of the servo motors and drive systems. These elements contribute to the overall precision and accuracy of the machine. Tool Changer and Tool Capacity: A tool changer allows for automatic tool changes during machining operations, improving efficiency and reducing downtime. Check the tool changer capacity of the CNC router to ensure it can accommodate the number and types of tools required for your applications. Dust Collection and Chip Management: CNC routing generates a significant amount of dust and chips. A robust dust collection system is necessary to maintain a clean and safe working environment. Consider the effectiveness of the machine’s dust collection system and the availability of chip management features such as chip conveyors or bins.

Support and Service: Evaluate the reputation and support offerings of the CNC router manufacturer or distributor. Look for a reputable company that provides reliable technical support, training, and after-sales service. Consider the availability of spare parts and the machine’s warranty period.

Safety Features: Safety should be a top priority when operating a CNC router. Look for safety features such as emergency stop buttons, safety interlocks, and protective enclosures. Consider additional safety options such as laser scanners or light curtains for enhanced operator protection.

Price and Return on Investment: Consider your budget and the long-term return on investment. While it’s essential to find a machine within your budget, prioritize quality, reliability, and performance over the initial cost. A well-built and efficient CNC router will provide higher productivity and longevity, resulting in better returns in the long run.

Dust Collection and Chip Management: CNC routing generates a significant amount of dust and chips. A robust dust collection system is necessary to maintain a clean and safe working environment. Consider the effectiveness of the machine’s dust collection system and the availability of chip management features such as chip conveyors or bins.

Support and Service: Evaluate the reputation and support offerings of the CNC router manufacturer or distributor. Look for a reputable company that provides reliable technical support, training, and after-sales service. Consider the availability of spare parts and the machine’s warranty period.

Safety Features: Safety should be a top priority when operating a CNC router. Look for safety features such as emergency stop buttons, safety interlocks, and protective enclosures. Consider additional safety options such as laser scanners or light curtains for enhanced operator protection.

Price and Return on Investment: Consider your budget and the long-term return on investment. While it’s essential to find a machine within your budget, prioritize quality, reliability, and performance over the initial cost. A well-built and efficient CNC router will provide higher productivity and longevity, resulting in better returns in the long run.

5 Axis CNC Wood Milling Machine High-speed Spindle: CNC wood milling machines are equipped with high-speed spindles capable of rotating at varying speeds to accommodate different types of cutting tools and materials.

High-speed Spindle: CNC wood milling machines are equipped with high-speed spindles capable of rotating at varying speeds to accommodate different types of cutting tools and materials.

Automatic Tool Changer (ATC): An ATC allows the machine to automatically change tools during the machining process, increasing efficiency and reducing downtime.

Vacuum Tables or Clamping Systems: Workpieces are typically secured to the machine bed using vacuum tables or clamping systems to ensure stability during machining.

Automatic Tool Changer (ATC): An ATC allows the machine to automatically change tools during the machining process, increasing efficiency and reducing downtime.

Vacuum Tables or Clamping Systems: Workpieces are typically secured to the machine bed using vacuum tables or clamping systems to ensure stability during machining.

|

| Excerpt | |

| Footnotes |