| You are currently viewing a revision titled "Best CNC Wood Carving Machine – ATC", saved on June 2, 2025 at 7:44 pm by Milne Fyhn | |

|---|---|

| Title | Best CNC Wood Carving Machine – ATC |

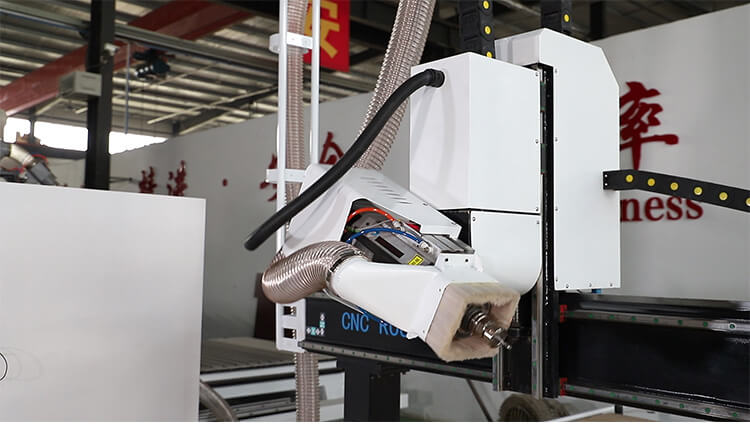

| Content | A CNC wood carving machine, also known as a CNC router or CNC woodworking machine, revolutionizes the woodworking industry with its precision, automation, and versatility. This advanced computer-controlled device combines cutting-edge technology with woodworking tools to achieve intricately carved designs, precise cuts, and efficient production processes.

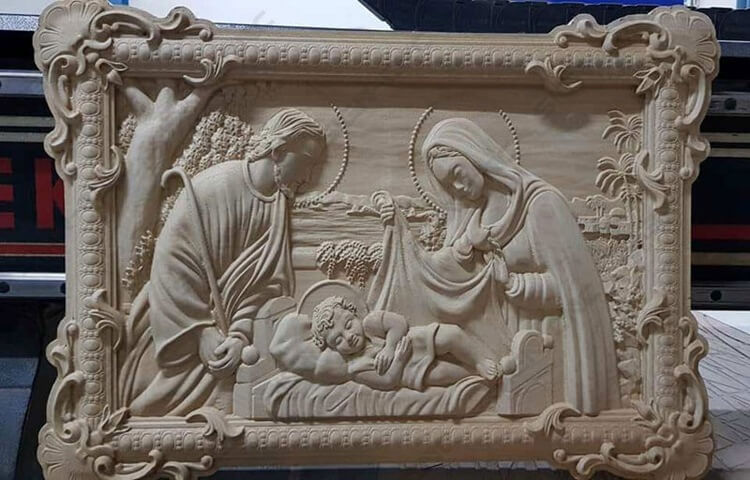

Best CNC Wood Carving MachineThe CNC Wood Carving Machine has transformed the woodworking industry by offering unparalleled precision, efficiency, and design flexibility. Its advanced features, automated operation, and versatility make it an indispensable tool for professionals and enthusiasts alike. With its ability to create intricate and customized designs, this machine has opened up new horizons for creativity in woodworking and beyond. The machine supports various cutting tools, including router bits, drills, and engraving tools. This versatility allows for a wide range of carving techniques, such as relief carving, 3D carving, and lettering.

ATC-Automatic Tool Changer machine

The machine supports various cutting tools, including router bits, drills, and engraving tools. This versatility allows for a wide range of carving techniques, such as relief carving, 3D carving, and lettering.

ATC-Automatic Tool Changer machine

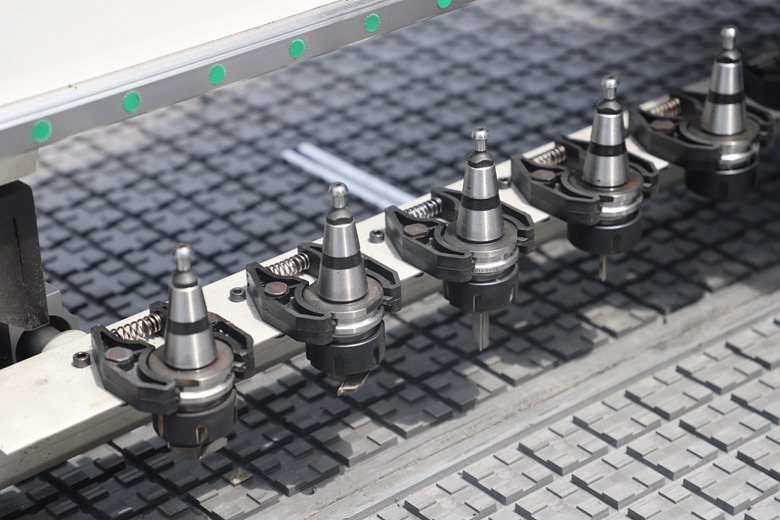

The ATC feature of the machine allows for the automatic changing of cutting tools, which can be pre-loaded into a tool carousel or magazine. This means that the machine can switch between different cutting tools without the need for manual intervention, saving time and increasing efficiency. The ATC system can also include a tool length sensor, which can automatically measure the length of each tool and adjust the cutting depth accordingly.

Industrial CNC routers with ATC typically have a large working area, allowing for the processing of large workpieces. They can also have multiple spindles, which can work simultaneously on different areas of the same workpiece or on different pieces at the same time. This can further increase productivity and efficiency.

Whether you’re a professional woodworker or a manufacturer, the Industrial ATC CNC Router is an excellent choice for your CNC routing needs. Contact us today to learn more about this machine and how it can help take your projects to the next level.

The ATC feature of the machine allows for the automatic changing of cutting tools, which can be pre-loaded into a tool carousel or magazine. This means that the machine can switch between different cutting tools without the need for manual intervention, saving time and increasing efficiency. The ATC system can also include a tool length sensor, which can automatically measure the length of each tool and adjust the cutting depth accordingly.

Industrial CNC routers with ATC typically have a large working area, allowing for the processing of large workpieces. They can also have multiple spindles, which can work simultaneously on different areas of the same workpiece or on different pieces at the same time. This can further increase productivity and efficiency.

Whether you’re a professional woodworker or a manufacturer, the Industrial ATC CNC Router is an excellent choice for your CNC routing needs. Contact us today to learn more about this machine and how it can help take your projects to the next level.

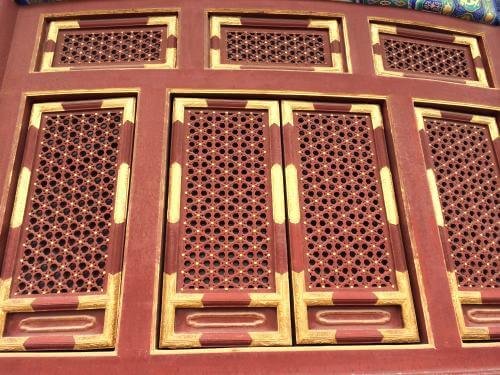

Advantages and Features of Best CNC Wood Carving Machine1. The CNC wood router machine with disc ATC system is an economical processing center with linear type knife library. The main accessories of the CNC machine are from world top brand. 2. The CNC woodworking machine comes with an Italy 9.0KW HSD air-cooled spindle, and the drive system adopts Japan servo motor. 3. Vacuum adsorption table, high adsorption power can adsorb different sizes material. 4. Intelligent processing cross-border protection is to prevent the mechanical impact phenomenon caused by the excessive design layout then processing format. 5. The Syntec control system can do multi-level 3D processing automatically. 6. The wood CNC machine can do three-dimensional processing with fast, smoothly carving/cutting, and it can be realized off-line operation. 7. Dust cover for Z axis, Y guide and rack in the same side. 8. High speed and efficiency and carved smooth clear. 9. The woodworking CNC machine adopts 4th axis rotary device, which can process cylinder materials, such as wood legs, chair legs. The rotary diameter and length can be optional. Best CNC Wood Carving Machine ApplicationsWoodworkingThe CNC Wood Carving Machine finds extensive use in the woodworking industry for creating furniture, cabinetry, decorative panels, doors, and moldings. It enables woodworkers to add intricate details and customized designs to their creations, enhancing their aesthetic appeal.

Art and SculptureArtists and sculptors utilize the CNC Wood Carving Machine to bring their imaginative designs and sculptures to life. The machine allows for precise and intricate carving, enabling artists to explore new creative possibilities and push the boundaries of their craft.

Signage and Decorative ItemsThe machine is widely employed in the production of personalized signs, plaques, nameplates, and decorative items. It can carve intricate letters, logos, and patterns onto wooden surfaces, providing a professional and eye-catching finish。

Education and Hobbyist ProjectsThe CNC Wood Carving Machine has become increasingly popular among educational institutions and hobbyists. It serves as a valuable tool for teaching woodworking skills and enables enthusiasts to pursue their passion for carving intricate designs at home.

cnc wood carving machine for saleA CNC wood carving machine, also known as a CNC router or CNC woodworking machine, revolutionizes the woodworking industry with its precision, automation, and versatility. This advanced computer-controlled device combines cutting-edge technology with woodworking tools to achieve intricately carved designs, precise cuts, and efficient production processes.Parts of the CNC wood carving machineAs mentioned, the CNC wood carving machine can be divided into two parts, and its different parts can be identified. In general, the parts used in the CNC carving machine are:Main chassisThe main chassis involves the body and the overall chamber of the CNC machine. Which is responsible for holding the various parts. The presence of the main chassis is very important for the operation of the machine. Also prevents the creation of noise and vibration of various parts during operation.Cutting toolThe cutting tool is crucial in determining the type of CNC machine and may vary depending on the different models. In a CNC carving machine, the drill is mainly used for engraving. The most common type of tool in wood carving machines is 8-headed machines that can cut eight samples of work simultaneously.SpindleThe main factor in the connection between the mechanical part and the intelligent part of the CNC carving machine is the spindle. In fact, this part acts as a communication bridge that converts the commands issued by the device control software into movement on the axes. The overall speed of the machine is set by the spindle speed.

AxesThe main factor in the movement of the cutting tool in different directions and even the movement of the machine table are the axes. The more axes in a machine, the more the machine will be able to move in different directions. Currently, CNC machines are made with two, three, four, and even five axes that provide movement in the X, Y, and Z directions. These axes are useful in creating complex and engraved patterns for rigid industrial designs.Electrical control panelThe electric control panel provides the operator with physical space. Similar to the software control space of the machine, and the operator uses it to determine in which directions. Also at what speed the cutting tool moves and in which parts of the sample it performs better.

Machine control softwareThe control software of the machine acts as artificial intelligence. In fact, the brain of the machine and the operator in this software defines how the axes move and how the cutting tool works on the wood. The software used in these machines is usually CAM software. But some companies may try to create specialized software for their product. |

| Excerpt | |

| Footnotes |