Welcome to the future of woodworking and furniture production. Our Panel Furniture Machines, which encompass the Edge Banding Machine, Panel & Beam Saw Machine, Sliding Table Saw, Side Hole Drilling Machine, and Hinge Boring & Drilling Machine, are the key to achieving unparalleled precision and efficiency.

CNC Panel Furniture Cutting Machine

Our

Panel Furniture Machines are renowned for their standout features. For instance, their advanced technology ensures precision and accuracy, while streamlined processes reduce production time and labor costs. This not only gives you a competitive edge but also ensures a solid return on investment due to the machines’ durability.

Today we will focus on introducing the automatic woodworking cutting machine。

The

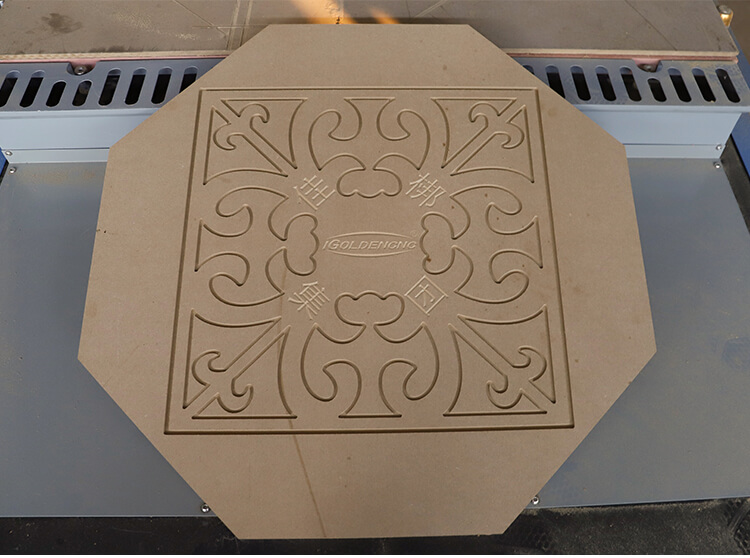

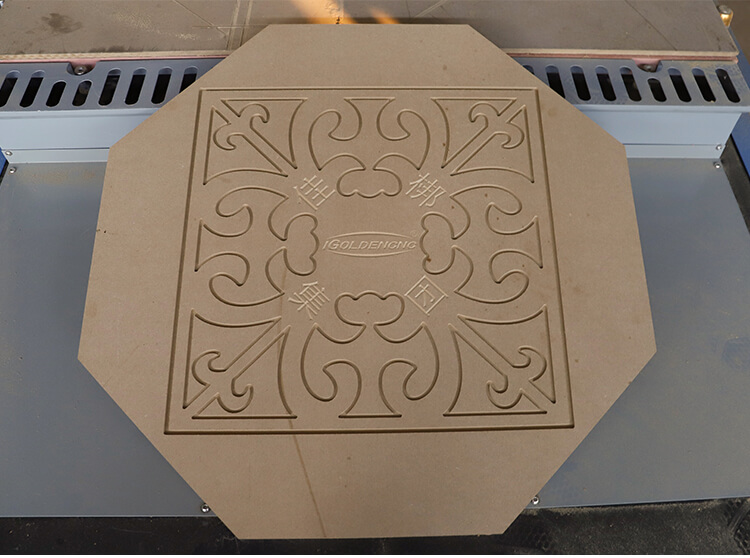

nesting CNC machine is a computer numerical control equipment specially designed for the

production of panel furniture line. It is also known as CNC nesting machine for sale, furniture making machine, CNC router nesting near me, nesting CNC router for furniture, furniture manufacturing machine, cabinet CNC machine, kitchen cabinet door making machine, CNC machine for cabinet making, cabinet door machine for sale, etc.

Nesting CNC machine is a smart machine tool in customized panel furniture production including cabinet door making, closet door making, home door making, wardrobe making, home decoration making, cabinets making, home furniture making, shop and office furniture making. In the production process, the operator just as porters, the Intelligent CNC nesting machines can realize automatic paste barcode, automatic feeding, drilling, slotting, cutting, automatic uploading, automatic retrieval processes for cutting side hole, slot on the back, back hole, the whole process don’t need human judgment, automatic processing, get rid of the dependence of woodworking professional and technical workers.

Besides, automatic feeding CNC nesting machine instead of the traditional push table saw or precision saw, to prevent the occurrence of work-related injuries, the health of employees is guaranteed.

Features and Advantages of the CNC Panel Furniture Cutting Machine

1. Increase the plate utilization by 40% The nesting cabinet CNC machine adopts a milling tool to cut the material, which can be arbitrarily turned to cut special-shaped workpieces and improve the utilization rate of the plate.

2. Labor saving One person can operate multiple nesting CNC machines, which greatly saves labor costs and reduces production costs.

3. Reduce labor intensity The nesting CNC router machine can be equipped with automatic loading and unloading system, making the operation easier and simpler. It greatly reduces the labor intensity of workers.

4. High safety If you do not pay attention when using the table saw, it is easy to hurt your hands and cause unnecessary accidental injuries. While the safety factor of the nesting wood CNC router is higher, which will basically not cause personal injury.

5. Better vacuuming effect The nesting CNC machine for wood is equipped with a double-cylinder vacuum cleaner. And its vacuuming effect is 3-5 times higher than that of the table saw.

6. Higher productivity The wood nesting CNC machine adopts full automatic loading and unloading system. At the same time, the nesting workload is 1.5 times that of ordinary manual cutting.

Panel Furniture Cutting Machine Projects

Wooden furniture industry: solid wood and composite door, cupboard door, sliding door, paint door, paint door, flexible packaging, plate carving, wood carving, machining, antique mahogany furniture, solid wood panel furniture murals carved, etc;

CNC machines offer high precision and accuracy in cutting. The computer-controlled system ensures consistent and exact cuts, resulting in precise fitting and alignment of furniture components. This accuracy is especially important for panel-based furniture where seamless joints and precise dimensions are required.

CNC panel furniture cutting machines are designed for high efficiency and productivity. Once the program is set up, the machine can operate continuously, cutting multiple panels with consistent quality and speed. This helps in streamlining production processes and reducing manual labor.

CNC machines allow for customization and design flexibility in furniture manufacturing. The cutting program can be easily modified to accommodate different designs, shapes, and sizes. This enables furniture manufacturers to offer a wide range of customized products to meet customer preferences and market demands.

If your woodworking projects involve large workpieces, you should consider the work area, sometimes called the cutting area or “envelope.’ On a CNC router, the work area is the travel limits in the X, Y, and Z axes. Deciding how you plan to use your machine determines your required work area. For example, a desktop CNC router with a 24” x 24” work area means you have that amount in which to work. However, even though the 24” in the X-axis (width) is limited because of the gantry supports, the Y-axis capacity is effectively limitless. Almost every machine allows for external support or a table extension for long workpieces. Of course, if your goal is sign-making from 4 ft. x 8 ft. plywood pieces, you’ll need to look at models that can accommodate those workpieces. Standard larger table sizes include the 4’ x 8’ and 5’ x 10’.

How to Choose the Right Panel Furniture Machine?

Selecting the perfect Panel Furniture Machinery for your specific needs involves careful considerations. For instance, when assessing the quantity of furniture pieces you plan to produce, you need to determine the machine’s capacity. Additionally, confirming that the machine can handle the materials you intend to use, whether it’s wood, MDF, or other materials, is crucial. Invest in our Panel Furniture Machines to transform your woodworking business. Contact us today to explore the perfect solutions tailored to your unique needs and propel your furniture production capabilities to new heights. Don’t miss the opportunity to enhance your furniture manufacturing processes with precision, efficiency, and versatility.

CNC machines offer high precision and accuracy in cutting. The computer-controlled system ensures consistent and exact cuts, resulting in precise fitting and alignment of furniture components. This accuracy is especially important for panel-based furniture where seamless joints and precise dimensions are required.

CNC machines offer high precision and accuracy in cutting. The computer-controlled system ensures consistent and exact cuts, resulting in precise fitting and alignment of furniture components. This accuracy is especially important for panel-based furniture where seamless joints and precise dimensions are required.