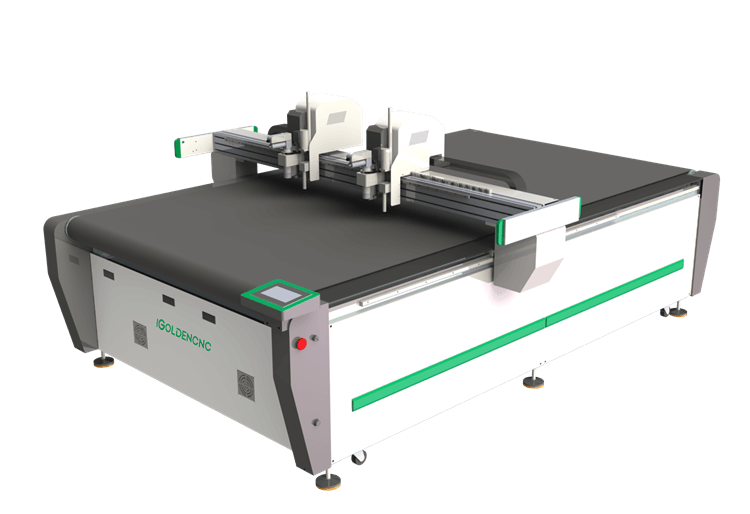

Digital Fabric Cutting Machine are widely used in industries such as textile manufacturing, upholstery, packaging, automotive, and signage. They offer the advantages of high precision, versatility, and automation, allowing for complex cutting patterns and designs. The CNC control system ensures repeatability and consistency in the cutting process, making these machines valuable tools in modern production environments.

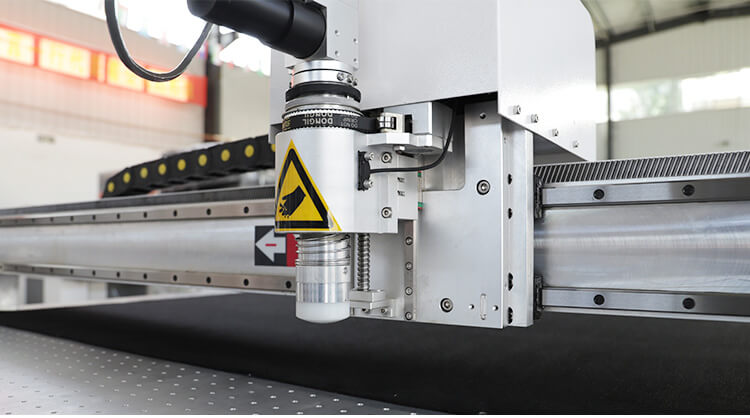

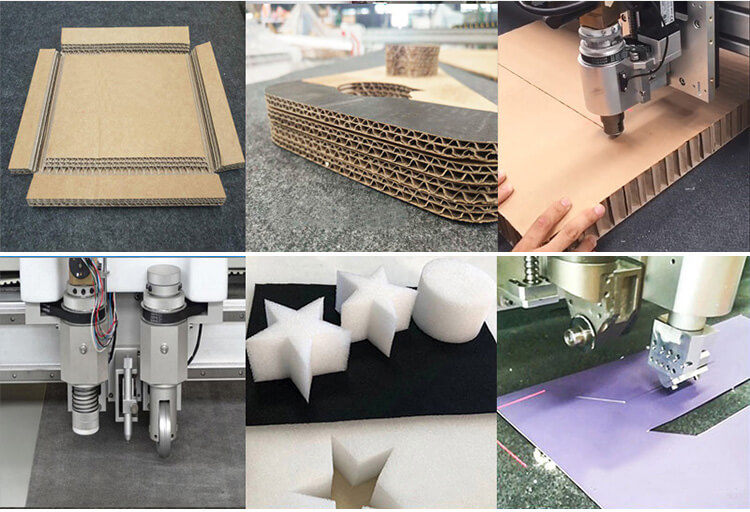

The CNC Fabric vibrating knife cutting machine is a cutting device mainly used for processing flexible materials. The vibrating knife cutting machine utilizes the high-frequency vibration of the vibrating knife to achieve the purpose of cutting. It has processing advantages such as flat incision, high cutting precision, fast cutting speed, and flexible processing.

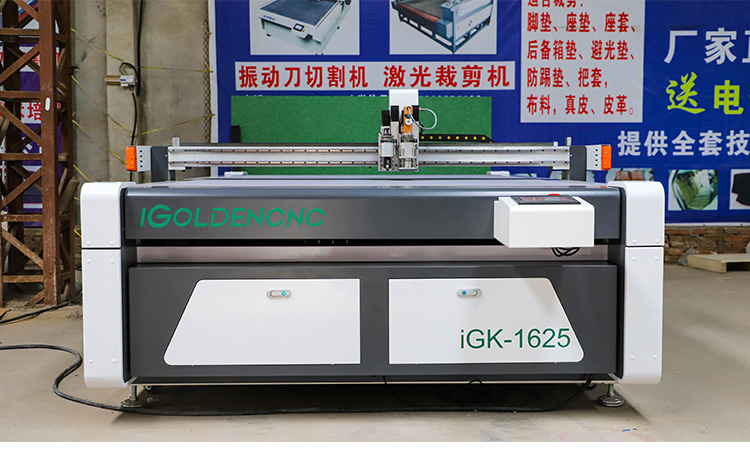

CNC oscillating knife cutting machine is carried on the multi-tool cutting head–Vibration knife, Oblique knife, Circular knife, Punching knife, Milling knife,Punch roller and Marking pen. CCD camera and Projector are optional for more precise cutting.

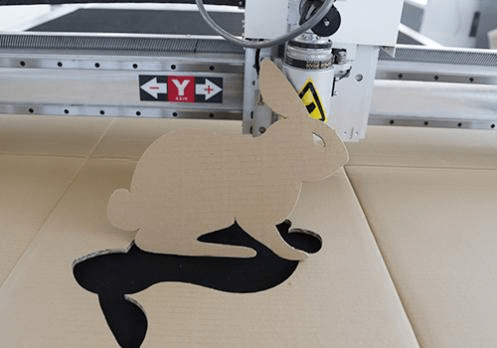

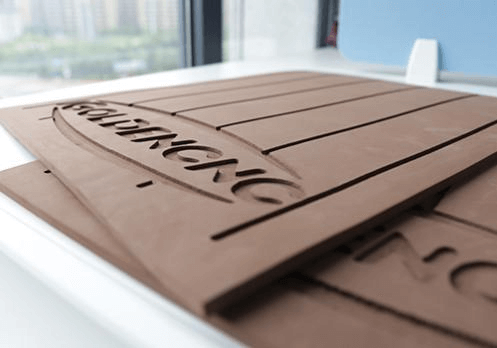

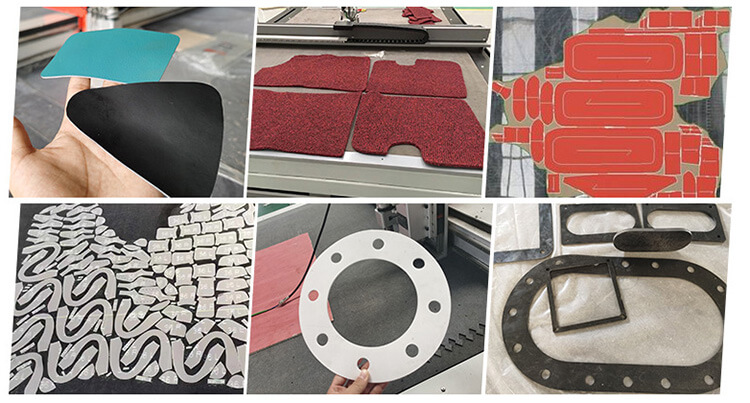

IGOLDENCNC high-performance tools can crimp and cut all commonly used packaging materials with a high-quality level. A vibrating knife option is an important tool for companies that need to process flexible materials. These flexible materials include packaging foam, foam core, blender foam, corrugated plastic, or cardboard. These materials all pose challenges to traditional router planning or cutting tools, but the “saw action” of the oscillating knife makes it easy to cut these materials, providing a clean cutting edge without fraying.

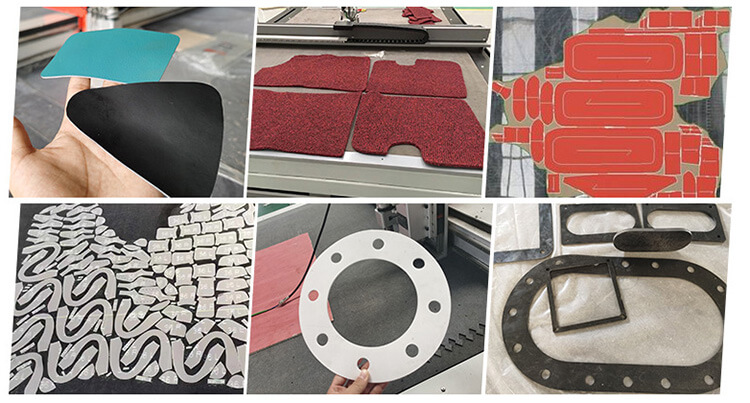

Application Materials:

Used for cutting leather, gasket, PP, PE, EVA, PTFE, ETFE, carpet, carton, wood, MDF, PVC, acrylic, cardboard, rubber, corrugated carton, foam, leather, composite materials, cardboard, corrugated board, honeycomb paper, plastic film, fiber paper, plastic box, resilient glue, rubber cloth, etc.

Features of CNC Vibrating Knife Cutting Machine

- 1300X2500mm working size

- Oscillating Knife Cutter

- Creasing Wheel

- MCGS CUT Panel Controller

- Servo Motor and Driver

- Helical Rack and Pinion and Taiwan TBI ball screw

- Taiwan PMI Linear Square Guide Rail

Digital Fabric Die Cutting

Digital Fabric Die Cutting cuts shapes not easily cut with a rotary cutter. Digital Fabric Die Cutting is helpful to people who have a hard time cutting manually. Digital Fabric Die Cutting is an accurate method of cutting. Digital Fabric Die Cutting allows you to draw your own shapes.

An Industrial Automatic Fabric Cutting Machine is a highly efficient and precise tool used in various industries.An oscillating cutting machine is a specialized tool designed to cut various materials using a blade that moves in a rapid back-and-forth (oscillating) motion. These machines are widely used in industries such as textiles, automotive, packaging, and construction due to their precision and versatility.

Industrial Fabric Cutting Machine

Industrial fabric cutting machines equipped with vibrating knives utilize rapid oscillating movements to cut through fabric with precision and speed. The vibrating knife moves back and forth at high frequencies, allowing it to slice through multiple fabric layers simultaneously. This oscillating action, combined with adjustable cutting pressure, enables smooth and accurate cuts without damaging the fabric.

The cutting plotter cuts with vibriting knife, not by laser. So it causes no burning to the materials. No smell.

CNC fabric knife cutting machines are suitable for small businesses that want to increase production efficiency, reduce labor costs, and improve product quality. However, small businesses should consider their budget and production volume when investing in CNC knife cutting machines. It’s important to choose a machine that suits the business’s specific needs and has a reasonable return on investment. Finally, adequate operator training is essential to fully utilize the technology and maximize the benefits.

Advantages of Automatic Fabric Cutting Machine

1. Increased Productivity

Vibrating knife technology allows fabric cutting machines to achieve incredibly high cutting speeds without compromising quality. This significantly improves productivity and enables bulk production of garments, home textiles, and other fabric-based products.

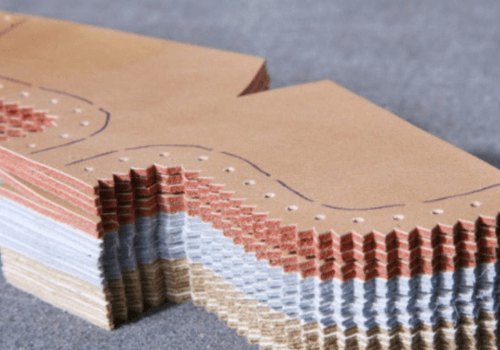

2. Precise Multi-Layer Cutting

The oscillating motion of a vibrating knife facilitates precise cutting through multiple fabric layers in one pass. This stacked cutting capability is ideal for industrial applications requiring high-volume production of pattern pieces.

3. Minimal Fabric Damage

Unlike rotating blades, vibrating knives apply an even pressure along the entire cutting edge, reducing friction and heat buildup. This results in clean cuts with less fabric distortion, frayed edges or burn marks.

4. Longer Blade Life

Vibrating knives experience less wear and tear compared to rotating blades since there is no grinding action during cutting. As a result, vibrating knife blades can last up to 10 times longer, reducing overall replacement costs.

5. Customizable Settings

The oscillation frequency and cutting pressure of vibrating knives can be customized based on the fabric thickness and density. This ensures optimal performance for a wide variety of materials.

Benefits of Using a CNC Fabric Cutting Machine:

- Accuracy: Minimizes material wastage and ensures high precision in cutting.

- Efficiency: Enhances production speed and reduces downtime.

- Cost-Effective: Lowers labor costs and reduces fabric wastage.

- Consistency: Produces uniform cuts and maintains consistent quality.

- Flexibility: Adaptable to various production needs and can handle different fabric types.

Automatic Fabric Cutting Machine Applications:

- Fashion Industry: Used for cutting patterns for garments and accessories.

- Automotive Industry: Cuts materials for car interiors, seat covers, and upholstery.

- Furniture Manufacturing: Used for cutting fabric for sofas, chairs, and other upholstered furniture.

- Textile Industry: General fabric cutting for various textile products.

Choosing an Industrial Fabric Cutting Machine

When selecting a fabric cutting machine with a vibrating knife, consider:

- Maximum Cutting Width: The width should accommodate your standard fabric/textile sizes.

- Stack Cutting Capacity: Higher capacity machines can cut more layers per pass for bulk production.

- Control System: Look for precision digital controls and programmable cutting parameters.

- Blade Type: Choose replaceable vibrating knife blades for cost-effectiveness.

- Safety Features: Look for light curtains, emergency stops and safeguarding around blades.

- Maintenance & Support: Consider the ease of regular maintenance and support availability.lution for many industrial fabric cutting applications.

What materials can be cut with a CNC knife cutting machine?

CNC knife cutting machines are versatile and can cut through a wide range of soft and hard materials. Some examples include foam, rubber, leather, fabrics, composites, plastics, cork, paper, and even wood. The machines can also cut intricate patterns and designs into the material, making them ideal for creating customized products.

CNC oscillating knife cutting machines are a popular type of CNC knife cutting machine that works by oscillating a tangentially-mounted knife to cut through materials. This type of machine is suitable for cutting softer materials, such as foam, gaskets, textiles, and rubber. The oscillating knife can adjust its speed and depth of cut, making it ideal for creating intricate shapes and accurate cuts. Additionally, this type of machine can be integrated with various software programs, allowing for a seamless transition from design to production.

How Do Digital Knife Cutting Machines Work?

Digital knife cutting machines are an essential tool for many industries, from clothing manufacturing to packaging. They offer a level of precision and accuracy that manual cutting tools cannot match. However, many people are still unaware of how these machines work.

Digital Cutters work by software programming, which directs the knife’s movement and controls the speed, depth, and pressure of the cut. The software used for programming the digital cutter’s movements is specifically designed to increase accuracy and precision. The software also allows the user to create complex shapes and designs that are not possible with manual cutting tools.

The cutting blade is controlled by a motor that moves it in a specific direction and, depending on the material’s thickness, sets the pressure of the cut. The machine has sensors that detect the position of the blade and adjust its path to ensure the correct shape of the desired cut. The software program also calculates the most efficient cutting path, avoiding the need for the user to design the cutting path manually.

There are two types of digital cutting machines, flatbed, and roll-fed. Flatbed cutters are suitable for cutting thicker materials like plastic and leather, while roll-fed cutters are ideal for thin materials like paper and fabric. Both types of cutters offer excellent cut quality and precision, with the type you need depending on your industry and the material you need to cut.

Digital cutting machines have many benefits, including increased precision, faster production times, reduced operator fatigue, and the ability to work with multiple materials. They also reduce material waste, as they can cut very close to the edge of the material, minimizing scrap. The software program used to control the machine can also more quickly and easily adjust to changes in design.

Digital knife cutting machines have revolutionized the way many industries approach cutting and have allowed them to increase their productivity, save time, and reduce waste. They offer unparalleled accuracy and precision, making them an essential tool for many different manufacturing sectors. With the advantages, these cutting machines provide, it is not difficult to see why they have become a necessary investment for any business that requires an efficient and reliable cutting device.

Discussion (0)

There are no comments for this doc yet.