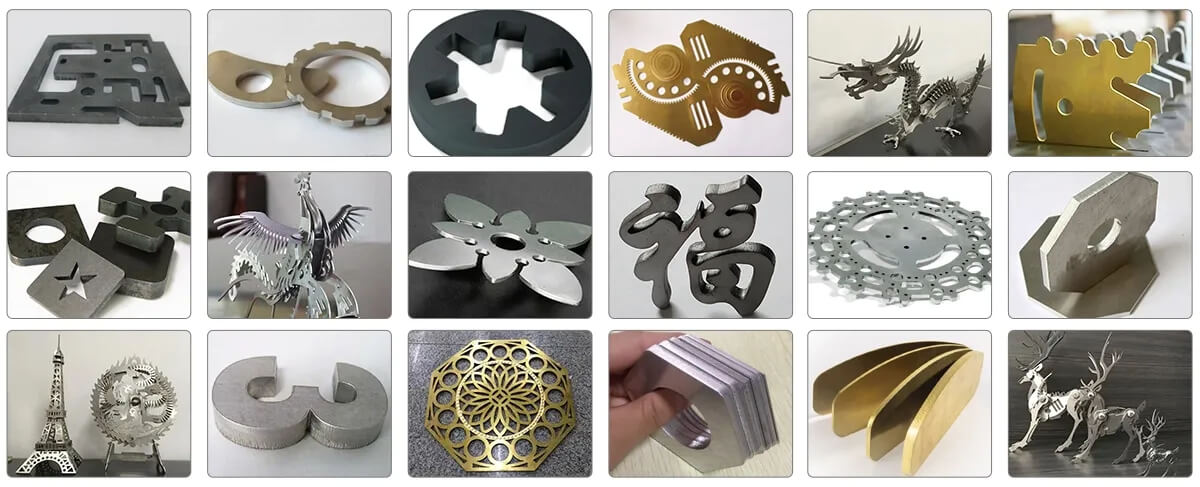

High power laser cutting machine is a type of industrial equipment that uses a laser beam to cut through a variety of metal. The laser beam is generated by a high-power laser and is focused through a lens to create a narrow, intense beam of light that can cut through the material.High power metal laser cutting machines have revolutionized the manufacturing and industrial sectors with their exceptional capabilities. This advanced technology utilizes high-power lasers to precisely cut through various metal materials, offering numerous advantages and applications across diverse industries. In this article, we will explore the key benefits and versatile applications of high power metal laser cutting machines.

The laser cutting process involves directing the laser beam at the material to be cut, which causes the material to heat up and melt or vaporize. The laser beam is typically controlled by a computer, which directs the beam along the desired cutting path. The resulting cut is precise and clean, with minimal kerf (the width of the cut).

When selecting a high power laser cutting machine, some factors to consider include the power of the laser, the size of the cutting bed, the thickness of the materials it can cut, the speed of cutting, and the level of precision required. It’s also important to consider the safety features of the machine, such as protective enclosures and safety interlocks.

High-power metal laser cutting machine are advanced tools used primarily in the industrial sector for precision cutting of various types of metal materials. These machines use high-powered lasers to melt, burn, vaporize, or blow away material, resulting in a high-quality, finish-ready cut. Here’s an overview:

Key Components:

- Laser Generator: This is the heart of the machine, generating a high-power laser beam capable of cutting through metal.

- CNC Controller: A computer numerical control (CNC) system is used to guide the laser and carry out the cuts as per the programmed instructions.

- Cutting Head: This component focuses the laser beam onto the material. It also has a nozzle that directs assist gas, like oxygen or nitrogen, to the cutting zone to eject the molten metal and protect the lens from splashes.

- Machine Bed: This is the flat, stable surface where the material being cut is placed.

- Chiller: High-power lasers generate significant heat, and a chiller is used to cool the laser and the optics.

- Exhaust System: This system removes the fumes and particles created during the cutting process.

Applications of High Power Metal Laser Cutting Machines

- Automotive Industry: In the automotive sector, precision and efficiency are paramount. High power metal laser cutting machines are used to fabricate complex parts, including chassis components, exhaust systems, and body panels. The ability to work with various metals makes them indispensable in the production of diverse vehicle models.

- Aerospace and Aviation: The aerospace industry demands components of utmost precision and reliability. Laser cutting technology is employed to manufacture intricate parts such as turbine blades, wing components, and brackets, ensuring safety and optimal performance of aircraft.

- Construction and Architecture: From intricate metal facades to structural elements, high power metal laser cutting machines play a crucial role in the construction and architecture sectors. They enable architects and engineers to bring their visionary designs to life with unmatched precision.

- Electronics and Technology: In the electronics industry, where miniaturization and precision are critical, laser cutting machines are used to produce precise circuits, connectors, and enclosures for electronic devices.

- Medical Devices: High power metal laser cutting machines are instrumental in producing medical devices and equipment with precise shapes and dimensions. From surgical instruments to implants, laser cutting ensures high-quality products with biocompatibility.

- Energy and Power Generation: For the energy sector, laser cutting is used in the fabrication of components for renewable energy systems, power generation equipment, and pipelines. Its accuracy and versatility contribute to the efficient operation of these critical systems.

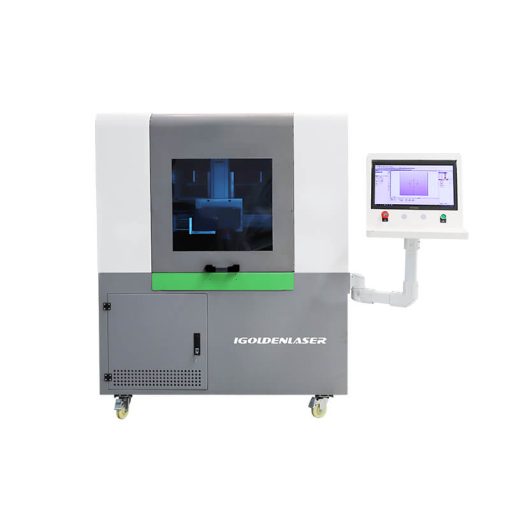

A fiber laser cutting machine is an industrial tool that utilizes a high-power laser to cut through materials. Fiber laser cutters offer several advantages over traditional CO2 laser cutters such as faster speeds, higher quality cuts, and the ability to cut a wider variety of materials.

Fiber laser cutters work by using an optical fiber to transmit laser light from a semiconductor laser to the cutting head. The laser is focused through lenses to a tiny spot where it vaporizes the material being cut. Common materials that can be cut with a fiber laser include steel, stainless steel, aluminum and other non-ferrous metals as well as wood, plastic, and composite materials.

Fiber Laser Cutting Machine

The fiber laser cutter, based on functions, falls into the laser cutting machine for metal sheet, fiber laser tube cutting machine, and sheet and tube laser cutting machine. Each model of the fiber laser machine has multiple specifications and configurations.

Based on the fiber laser power, we provide 1000W / 1500W / 2000W / 3000W / 4000W / 6000W / 8000W fiber laser cutting machine and other high power laser cutting machines to realize your metal cutting designs, ideas, and plans.

In addition, there are multiple worktable sizes available for the laser sheet cutting machine. For example, 1530 fiber laser cutting machine, 1540 laser sheet cutting machine, 2040 CNC fiber laser cutter, 1560 sheet metal laser cutter, 2040 fiber laser cutting machine , 2060 fiber laser cutter, etc. Feel free to contact us if you want to know more about the fiber laser cutting system or the laser cutting service.

LASER CUTTING MACHINE

LASER CUTTING MACHINE

LASER CUTTING MACHINE

LASER CUTTING MACHINE

LASER CUTTING MACHINE

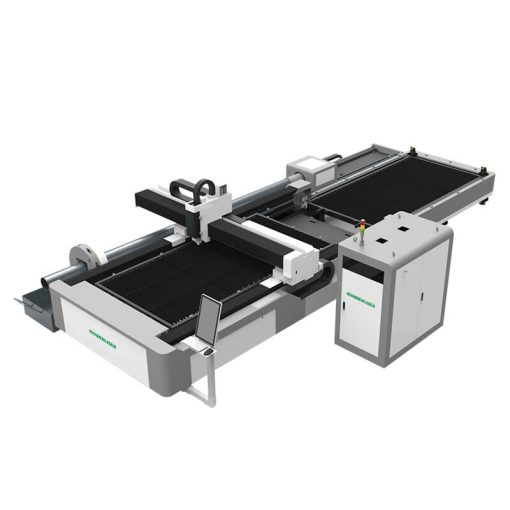

Metal Sheet and Pipe Laser Cutting Machine with Exchange Worktable

LASER CUTTING MACHINE

LASER CUTTING MACHINE

LASER CUTTING MACHINE

High-precision Glass Materials Laser Cutting & Drilling Machine

Sheet Metal Laser Cutting Machines

Sheet metal laser cutter is a type of automatic metal plate cutting system that uses CO2 or fiber laser beam with CNC controller to cut stainless steel sheet, chromium steel sheet, martensitic steel sheet, ferritic steel plate, austenitic steel plate, carbon steel sheet, mild steel sheet, hot & cold rolled steel sheet, galvanized steel sheet, pre-plated steel sheet, aluminum plate, zinc plate, copper & brass sheet, as well as titanium, gold, and silver.

Laser sheet metal cutters can deal with multi-variety, small-batch, customized, high-quality, short-delivery orders. It features with high precision, high speed, and high flexibility, which makes it to cut projects with special or complex shapes, and step-by-step replace the traditional sheet metal cutting tools, including plasma cutters, flame cutters, water jet cutters, CNC punching machines, CNC shearing machines, tin snips, and wire cutters. The sheet metal cutting tables (2×3, 2×4, 4×4, 4×8, 5×10, 6×12), laser generators (IPG, JPT, Raycus, MAX, RECI), and laser powers (150 watts, 180 watts, 220 watts, 300 watts, 1000 watts, 1500 watts, 2000 watts, 3000 watts, 4000 watts, 6000 watts, 8000 watts, 10000 watts, 12000 watts, 15000 watts, 20000 watts, 30000 watts, 40000 watts, 60000 watts) can be customized as your sheet metal cutting plans.

Tube & sheet metal laser cutter is a dual-purpose all-in-one fiber laser cutting machine for both sheet metals (including flat bars, R-panels, expanded metal gratings,) and tube profiles (including rectangular tubing, square tubing, round tubing, galvanized tubing, channel tubing, C purlins, Z purlins, angle and tubes). It can cut carbon steel, stainless steel, aluminum, iron, alloy, brass, copper, silver, and gold. One machine is multi-purpose, and the price is relatively high. It features with cast iron bed, rack and pinion transmission system, professional CNC sheet and pipe cutting system, high precision, full function, convenient use and simple operation.

A pipe cutting device is added on one side of the machine, and both the front chuck and the rear chuck are automatically clamped. The double chuck is driven by double synchronous motor to ensure the rotation accuracy of the pipe. The raw pipe is loaded from the left and rear ends of the machine, and the finished pipe is discharged from the left front end of the machine. Both the feeding and the blanking are supported by brackets. The all-in-one metal laser cutting machine adopts a special fiber laser cutting head and a capacitive non-contact high-level automatic tracking system. The cutting head is designed for beam shaping, with excellent beam quality. The equipped focusing lens can be used for cutting plates with different thicknesses, eliminating the trouble of replacing different focusing lenses.

Laser Metal Tube Cutting Machine

A laser metal tube cutting machine is an automatic CNC pipe cutter that uses fiber laser beam to cut round tubes, square tubes, rectangular tubes, oval pipes, elliptical tubes, hexagonal tubes, triangular tubes and some custom special shape pipes in a variety of metals, including stainless steel, carbon steel, mild steel, tool steel, alloy, aluminum, brass, copper, bronze and titanium. It is a dieless cutting system to cut any types of designs on metal pipes in any angle and direction. Compared with flame cutting, plasma cutting, wire cutting, and water jet cutting, the fiber laser tube cutter is easy to use with a high degree of automation, low cost, high speed and high quality, and the laser-cut metal precision is much higher without grinding.

Key Features of CNC Metal Laser Cutting Machines

- High Precision and Accuracy:

- Laser cutting offers extremely high precision, with the ability to cut intricate designs and tight tolerances.

- Capable of producing complex geometries and fine details.

- Speed and Efficiency:

- Faster cutting speeds compared to traditional cutting methods.

- Increased productivity due to reduced cutting times.

- Versatility:

- Suitable for cutting various types of metals, including stainless steel, carbon steel, aluminum, copper, and brass.

- Can handle different thicknesses and material properties.

- Clean Cuts and Minimal Waste:

- Produces smooth edges with minimal burrs, reducing the need for secondary finishing processes.

- Efficient material usage, minimizing waste and optimizing sheet layout.

- Automation and Integration:

- Often integrated with CAD/CAM software for streamlined design and cutting processes.

- Can be automated for continuous and unattended operation.

- Contactless Cutting:

- Non-contact process, reducing tool wear and tear.

- Minimizes material deformation and damage, especially for thin or delicate metals.

Common Applications for Fiber Laser Cutting

Here are some of the most popular applications where fiber laser cutting technology really shines:

Prototyping and low to medium volume production parts in metals like steel, aluminum and stainless steel.

Cutting complex nested parts from sheet metal for industries like automotive, aerospace, electronics and appliances.

Cutting precision parts for medical devices, instrumentation and other applications that require tight tolerances.

– Cutting parts for signs and displays where high edge quality is important for aesthetics.

– Cutting parts for the marine industry where corrosion resistance is key. Stainless steel is easily cut on fiber lasers.

– Cutting parts for heavy equipment, construction, agricultural, mining and other off-road vehicle applications.

– Cutting parts for small appliance, furniture and other consumer goods manufacturing.

The versatility and precision of fiber laser cutting machines make them well-suited for prototyping and low to medium volume production across many industries.

Discussion (0)

There are no comments for this doc yet.